Manual die notching system 1H

Manual die cutting system

This notching system is made to measure for die cutting operations on flexible or rigid profiles. The system is able to execute cutting operations on profiles of different shapes, made of different materials (rubber, PVC, TPE,…), with or without reinforcement.

How it works

The operator inserts manually a right and/or left piece into the equipment.

The operation is executed by a pneumatically operated die cutting unit / knives.

The operator removes the finished parts and loads new ones into the equipment.

Manual die notching system 2H

Manual die cutting system

This notching system is made to measure for die cutting operations on flexible or rigid profiles. The system is able to execute cutting operations on profiles of different shapes, made of different materials (rubber, PVC, TPE,…), with or without reinforcement.

How it works

The operator inserts manually a right and/or left piece into the equipment.

The operation is executed by a pneumatically operated die cutting unit / knives.

The operator removes the finished parts and loads new ones into the equipment.

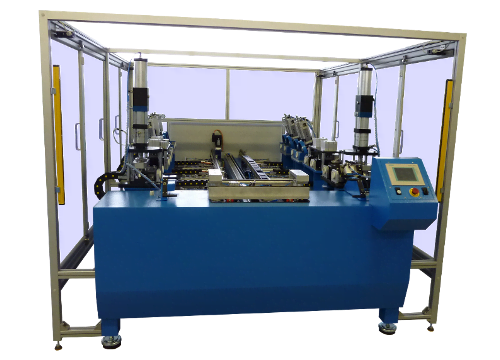

Automatic die cutting system

Automatic die cutting system

This type of system has been specially designed for the automatic execution of cutting, notching and die cutting operations on rigid profiles. The system is able to execute cuts on profiles of different shapes made of different materials (rubber, PVC, TPE,…) and with different types of metal supports (steel, aluminium,…).

Purpose

System specially conceived for shops engaging in large-scale manufacturing activities, requiring high quality cutting and die cutting processes, according to the most stringent quality criteria of the automotive industry.

How it works

The operator loads the pieces, either manually or not, in a storage zone, and an ad hoc clamping system keeps the pieces from moving during the various processing stages. Immediately after the start of the cycle, the overhead line moves the pieces to the next processing station. Cutting/die cutting operations are performed by different machining units specific to each processing station. Finished parts return to the operator for unloading (automatic unloading available on request).

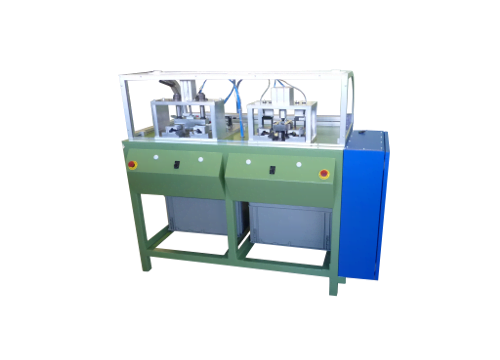

Manual die notching system 2H

Manual die notching system 2H

This type of semi-automatic system has been specially designed to execute cutting to size and die cutting operations on rigid profiles. The system is able to execute cuts on profiles of different shapes made of different materials (rubber, PVC, TPE,…) and with different types of metal supports (steel, aluminium,…).

Purpose

System specially conceived for shops engaging in large- and medium-scale manufacturing activities, requiring perfect cutting and die cutting processes, according to the most stringent quality criteria of car makers.

How it works

The operator loads the pieces manually into a confinement jig and an ad hoc clamping system keeps the pieces from moving during the process. The operator removes the finished parts and loads new pieces into the unit.

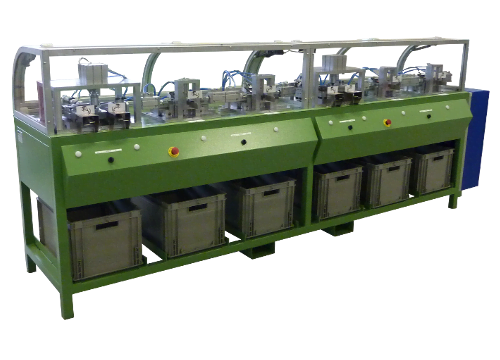

Manual die notching system 3H

Manual die notching system 3H

This type of semi-automatic system has been specially designed to execute cutting to size and die cutting operations on rigid profiles. The system is able to execute cuts on profiles of different shapes made of different materials (rubber, PVC, TPE,…) and with different types of metal supports (steel, aluminium,…).

Purpose

System specially conceived for shops engaging in large- and medium-scale manufacturing activities, requiring perfect cutting and die cutting processes, according to the most stringent quality criteria of car makers.

How it works

The operator loads the pieces manually into a confinement jig and an ad hoc clamping system keeps the pieces from moving during the process. The operator removes the finished parts and loads new pieces into the unit.

Manual die notching system 4H

Manual die notching system 4H

This type of semi-automatic system has been specially designed to execute cutting to size and die cutting operations on rigid profiles. The system is able to execute cuts on profiles of different shapes made of different materials (rubber, PVC, TPE,…) and with different types of metal supports (steel, aluminium,…).

Purpose

System specially conceived for shops engaging in large- and medium-scale manufacturing activities, requiring perfect cutting and die cutting processes, according to the most stringent quality criteria of car makers.

How it works

The operator loads the pieces manually into a confinement jig and an ad hoc clamping system keeps the pieces from moving during the process. The operator removes the finished parts and loads new pieces into the unit.