CUTTERTEC STEP BY STEP

CUTTERTEC STEP BY STEP

The off-line cuttertec machine allows you to cut to length profiles with or without metal carrier, coiled in bobbins.

Advantages:

Versatility, Flexibility, Accuracy and Speed

Versatile machine:

You want to run another program with different profiles? By changing guides and clamps our machine allows you to run an almost infinite number of cross sections.

Flexibility:

Our machine accepts, profile extruded with or without metal carries.

Accuracy:

Verey tight cutting tolerances

Circular cutting machine 2H-OL

Semi-automated off-line finishing system

New dual-blade cutting system specially designed for huge production volumes.

It consists of a bearing structure that can house different, fully automated processes:

Double cutting of rubber and reinforced rubber profiles

Drilling

Polyurethane injections into the bulb for profile bending zones

Marking

Advantages

Gaskets are cut to size in a single operation.

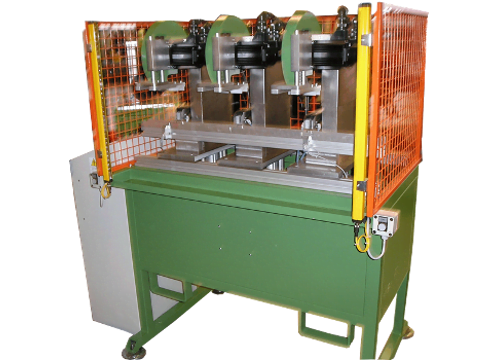

Circular cutting machine 3H-OL

Semi-automated off-line finishing system

New dual-blade cutting system specially designed for huge production volumes.

It consists of a bearing structure that can house different, fully automated processes:

Double cutting of rubber and reinforced rubber profiles

Drilling

Polyurethane injections into the bulb for profile bending zones

Marking

Advantages

Gaskets are cut to size in a single operation.

Cuttertec

Cutting System

Our CUTTERTEC machine range proposes cutting systems that are innovative, versatile and able to process a wide variety of materials. They can be used both on line, at a rate of up to 30m/sec, or off line.

For any need, we offer a dedicated, customised solution ensuring quick, top quality cutting processes, by means of disks, bayonet mechanisms, rotary blades.

All the machines in this range adopt an operator panel with a touch screen for parameter setting on user-friendly graphic pages.

The machines are also equipped with an innovative self-adjustment function, whereby, by entering the actual values of the first cut performed, the machine is able to cut the rest of the output, from the second piece on, with the utmost precision.

For improved cutting quality, disk cutters are fitted with a clamp, operated by a pneumatic cylinder, that blocks the profile in the desired position during the cutting process.

The clamp has housings to facilitate the use of dedicated cutting jigs for each individual profile, resulting in improved cutting efficiency.

Furthermore, Tecnofive supplies unloading belts of the desired length as well as material coil unwinding systems for off-line cutting operations.

A cutting machine

for every need

DISK CUTTERS

for gaskets in:

Rubber

Sponge

Reinforced rubber

Thermoplastic materials

BAYONET CUTTERS

for gaskets in:

Rubber

Sponge

Plastic materials

ROTARY BLADE CUTTERS

for gaskets in:

Non-reinforced rubber pipes

Cuttertec 1H

Cutting System

Our CUTTERTEC machine range proposes cutting systems that are innovative, versatile and able to process a wide variety of materials. They can be used both on line, at a rate of up to 30m/sec, or off line.

For any need, we offer a dedicated, customised solution ensuring quick, top quality cutting processes, by means of disks, bayonet mechanisms, rotary blades.

All the machines in this range adopt an operator panel with a touch screen for parameter setting on user-friendly graphic pages.

The machines are also equipped with an innovative self-adjustment function, whereby, by entering the actual values of the first cut performed, the machine is able to cut the rest of the output, from the second piece on, with the utmost precision.

For improved cutting quality, disk cutters are fitted with a clamp, operated by a pneumatic cylinder, that blocks the profile in the desired position during the cutting process.

The clamp has housings to facilitate the use of dedicated cutting jigs for each individual profile, resulting in improved cutting efficiency.

Furthermore, Tecnofive supplies unloading belts of the desired length as well as material coil unwinding systems for off-line cutting operations.

A cutting machine

for every need

DISK CUTTERS

for gaskets in:

Rubber

Sponge

Reinforced rubber

Thermoplastic materials

BAYONET CUTTERS

for gaskets in:

Rubber

Sponge

Plastic materials

ROTARY BLADE CUTTERS

for gaskets in:

Non-reinforced rubber pipes

Cuttertec 2H

Cutting System

Our CUTTERTEC machine range proposes cutting systems that are innovative, versatile and able to process a wide variety of materials. They can be used both on line, at a rate of up to 30m/sec, or off line.

For any need, we offer a dedicated, customised solution ensuring quick, top quality cutting processes, by means of disks, bayonet mechanisms, rotary blades.

All the machines in this range adopt an operator panel with a touch screen for parameter setting on user-friendly graphic pages.

The machines are also equipped with an innovative self-adjustment function, whereby, by entering the actual values of the first cut performed, the machine is able to cut the rest of the output, from the second piece on, with the utmost precision.

For improved cutting quality, disk cutters are fitted with a clamp, operated by a pneumatic cylinder, that blocks the profile in the desired position during the cutting process.

The clamp has housings to facilitate the use of dedicated cutting jigs for each individual profile, resulting in improved cutting efficiency.

Furthermore, Tecnofive supplies unloading belts of the desired length as well as material coil unwinding systems for off-line cutting operations.

A cutting machine

for every need

DISK CUTTERS

for gaskets in:

Rubber

Sponge

Reinforced rubber

Thermoplastic materials

BAYONET CUTTERS

for gaskets in:

Rubber

Sponge

Plastic materials

ROTARY BLADE CUTTERS

for gaskets in:

Non-reinforced rubber pipes

Disk cutting machine

Cutting System

Our CUTTERTEC machine range proposes cutting systems that are innovative, versatile and able to process a wide variety of materials. They can be used both on line, at a rate of up to 30m/sec, or off line.

For any need, we offer a dedicated, customised solution ensuring quick, top quality cutting processes, by means of disks, bayonet mechanisms, rotary blades.

All the machines in this range adopt an operator panel with a touch screen for parameter setting on user-friendly graphic pages.

The machines are also equipped with an innovative self-adjustment function, whereby, by entering the actual values of the first cut performed, the machine is able to cut the rest of the output, from the second piece on, with the utmost precision.

For improved cutting quality, disk cutters are fitted with a clamp, operated by a pneumatic cylinder, that blocks the profile in the desired position during the cutting process.

The clamp has housings to facilitate the use of dedicated cutting jigs for each individual profile, resulting in improved cutting efficiency.

Furthermore, Tecnofive supplies unloading belts of the desired length as well as material coil unwinding systems for off-line cutting operations.

A cutting machine

for every need

DISK CUTTERS

for gaskets in:

Rubber

Sponge

Reinforced rubber

Thermoplastic materials

BAYONET CUTTERS

for gaskets in:

Rubber

Sponge

Plastic materials

ROTARY BLADE CUTTERS

for gaskets in:

Non-reinforced rubber pipes

Hoses cuttertec OL

Sleeve Cutter

This type of cutter, fully made of stainless steel, has been designed to cut canvas rubber sleeves. The system includes a mobile carriage housing a support (jig) customised for the type of sleeve to be trimmed and a two-handed control that moves the support with the sleeve onto a fixed circular blade, lubricated with water, which cuts through the product. The machine may be equipped with a water collection tank to obtain a closed circuit with the aid of a submersible pump.

MULTITEC

Semi-automated off-line finishing system

New dual-blade cutting system specially designed for huge production volumes.

It consists of a bearing structure that can house different, fully automated processes:

Double cutting of rubber and reinforced rubber profiles

Drilling

Polyurethane injections into the bulb for profile bending zones

Marking

Advantages:

Gaskets are cut to size in a single operation.

Recovery cuttertec

Off-line semi-automatic reworking system for jointed profiles

New dual blade cutting system specially designed for use by production shops where profiles are jointed by means of a splicing film. It makes it possible to rework a profile previously jointed improperly, so as to greatly reduce the quantity of parts that have to be scrapped.

The system consists of two closely spaced circular blades that can cut the jointed portion of the profile by removing as little material as possible, so as to obtain a profile that is ready to be jointed again with the splicing system. It can be used both for all-rubber profiles and for metal reinforced profiles.

Rotary Blade cuttertec

Cutting System

Our CUTTERTEC machine range proposes cutting systems that are innovative, versatile and able to process a wide variety of materials. They can be used both on line, at a rate of up to 30m/sec, or off line.

For any need, we offer a dedicated, customised solution ensuring quick, top quality cutting processes, by means of disks, bayonet mechanisms, rotary blades.

All the machines in this range adopt an operator panel with a touch screen for parameter setting on user-friendly graphic pages.

The machines are also equipped with an innovative self-adjustment function, whereby, by entering the actual values of the first cut performed, the machine is able to cut the rest of the output, from the second piece on, with the utmost precision.

For improved cutting quality, disk cutters are fitted with a clamp, operated by a pneumatic cylinder, that blocks the profile in the desired position during the cutting process.

The clamp has housings to facilitate the use of dedicated cutting jigs for each individual profile, resulting in improved cutting efficiency.

Furthermore, Tecnofive supplies unloading belts of the desired length as well as material coil unwinding systems for off-line cutting operations.

A cutting machine

for every need

DISK CUTTERS

for gaskets in:

Rubber

Sponge

Reinforced rubber

Thermoplastic materials

BAYONET CUTTERS

for gaskets in:

Rubber

Sponge

Plastic materials

ROTARY BLADE CUTTERS

for gaskets in:

Non-reinforced rubber pipes

Sponge

Plastic materials

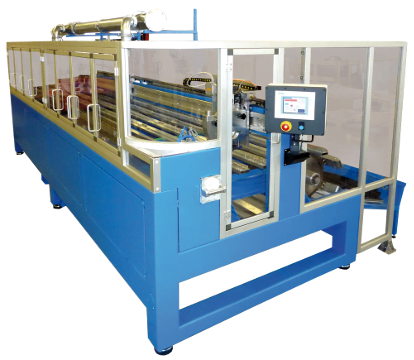

Workstation - cuttertec 2H-OL

Semi-automated off-line finishing system

New dual-blade cutting system specially designed for huge production volumes.

It consists of a bearing structure that can house different, fully automated processes:

Double cutting of rubber and reinforced rubber profiles

Drilling

Polyurethane injections into the bulb for profile bending zones

Marking

Advantages

Gaskets are cut to size in a single operation.

Workstation - cuttertec 3H

SCHEDA IN COSTRUZIONE

Workstation - cuttertec 3H-OL

Semi-automated off-line finishing system

New dual-blade cutting system specially designed for huge production volumes.

It consists of a bearing structure that can house different, fully automated processes:

Double cutting of rubber and reinforced rubber profiles

Drilling

Polyurethane injections into the bulb for profile bending zones

Marking

Advantages

Gaskets are cut to size in a single operation.

Workstation - cuttertec 4H

SCHEDA IN COSTRUZIONE