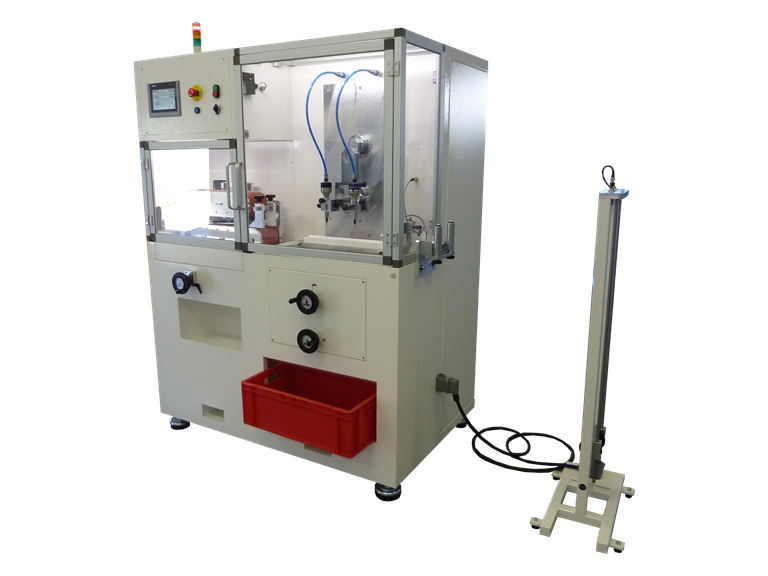

DRILLTEC 1H

Line drilling machine

The sponge bulbs are drilled directly on the extrusion line by means of an orbital drilling system synchronised with line speed:

Max speed of 30 m/minute without line stops during drilling operations.

Drill spacing programmable from a minimum of 100 mm to a maximum of 500 mm. Possibility to have from one to three drilling units as a function of the bulbs to be drilled.

In systems using two or three head, the drill heads are mounted on a single base, mechanically connected by means of cardan joints or electronically connected by means of a double brushless motor ensuring the synchronisation of the two drilling units.

Advantages

Holes are drilled without stopping the line

Flexible system that makes it possible to use different processing units in alternation

Possibility to work along different axes and at different inclinations

The sponge bulbs are drilled directly on the extrusion line by means of an orbital drilling system synchronised with line speed:

Max speed of 30 m/minute without line stops during drilling operations.

Drill spacing programmable from a minimum of 100 mm to a maximum of 500 mm. Possibility to have from one to three drilling units as a function of the bulbs to be drilled.

In systems using two or three head, the drill heads are mounted on a single base, mechanically connected by means of cardan joints or electronically connected by means of a double brushless motor ensuring the synchronisation of the two drilling units.

Advantages

Holes are drilled without stopping the line

Flexible system that makes it possible to use different processing units in alternation

Possibility to work along different axes and at different inclinations